The UN estimates that 17% of the world’s food production was wasted in 2019 between harvest, marketing and consumption, causing negative economic, social and environmental impact.

In this sense, in the 1st National Supply Chain Forum, promoted on 17 June by Brazilian Supermarket Association (ABRAS), the Minister of Agriculture, Livestock and Supply Tereza Cristina stated that Brazil needs to improve 2 points in its supply chain, traceability (check our article about traceability in the bovine chain here) and food waste.

Fabiano Coldebella, Commercial Manager of AgroFresh

In the fruit sector, an action to mitigate waste is the conservation with waxes or coatings. Recently the Brazilian Agricultural Research Corporation (Embrapa) in partnership with the Federal University of São Carlos (UFSCAR) and QGP Química developed the nanoemulsion of carnauba for conservation, which will be marketed by the company AgroFresh.

AgriBrasilis interviewed Fabiano Coldebella, Commercial Manager of AgroFresh Brazil, agronomist with an MBA in Strategic Agribusiness Management from FGV/RJ, about this technology.

AgriBrasilis – What is the Carnauba Nano Emulsion and what is the difference between traditional carnauba wax?

Fabiano Coldebella – One of our coatings sold in Brazil uses an innovative nano emulsion process to generate smaller particles for superior coating coverage and fruit protection. This nano emulsion technology was developed by Embrapa Instrumentation (part of the Brazilian Agricultural Research Corporation), UFSCar (the Federal University of São Carlos – Brazil) and QGP Química.

This coating, marketed as Tanwax C 18 Nano in Brazil, provides a protective membrane to reduce dehydration, providing excellent freshness preservation and food loss reduction for citrus and tropical fruits such as avocados, papayas and mangoes. Fruit coated with this solution can be dried quickly, generating a sustainability benefit of decreased energy usage and lower-cost operational efficiencies.

By the way, and in general, the terms “wax” and “coating” can be used interchangeably. These products provide a range of functional post-harvest crop protection, specifically dehydration reduction, weight loss and freshness extension. AgroFresh is using the term “coatings” to refer to all its products.

AgriBrasilis – When compared to nano emulsion and wax, what are the advantages and benefits?

Fabiano Coldebella – Coatings in general are primarily applied to fresh fruits to increase their post-harvest life by regulating the exchange of water and gases (oxygen and carbon dioxide). This primary function allows for less weight loss during storage and, in some cases, the alleviation of some postharvest physiological disorders such as chilling injury or rind breakdown. In addition, coatings can also provide shine and gloss to improve the fruit’s external appearance.

Fruits keep their ripening and respiration process after the harvest, and each one has a different metabolism, so the benefits aren´t equal. When we work with a living being, which continues its ripening and breathing process even after being harvested, as is the case with fruits, and knowing that they have different metabolic processes, we must always be careful not to generalize the benefits.

Tanwax C 18 Nano has shown interesting results for maintaining fruit quality, increasing shelf life. That is because it can decrease the metabolism of the fruit, changing the permeability maintaining more carbon dioxide and releasing the fruit’s oxygen and also preventing water loss.

For the grower, this result is reflected in better yields, for being able to maintain the weight and quality of the products, for consumers the advantage is having access to fresher and more tasty products, in addition to avoiding food waste in the chain.

AgriBrasilis – What is its importance for reducing food waste? Are there any estimates of how much loss can be reduced?

Fabiano Coldebella – According to the Food and Agriculture Organization of the United Nations (FAO), one third of the food is wasted before it can be consumed and 45% of the fruits of vegetables perishes before the consumption.

In other words, we have a long work ahead of us and any action that takes into account good agricultural practices can be important to reduce food loss and that is AgroFresh’s mission.

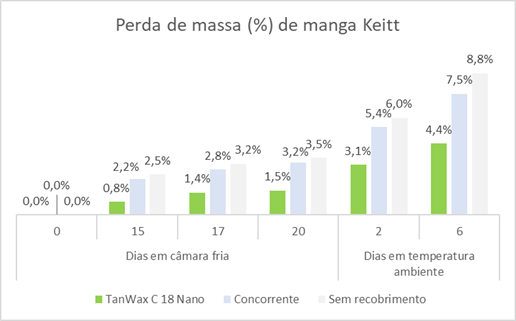

In commercial work carried out with Manga of the Keitt variety in Petrolina, Pernambuco, (Graph below), the carnauba nano emulsion reduced the mass loss by 41%, which means 3.08 percentage points. If we convert this to a container with 22,000 kg of fruit, it is possible to estimate that with the carnauba nano emulsion (TanWax C 18 Nano) could avoid the waste of 677.60 kg per container. This, as I mentioned earlier, is money for the producer and a more juicy, crunchy fruit with a better shelf life for the end consumer.

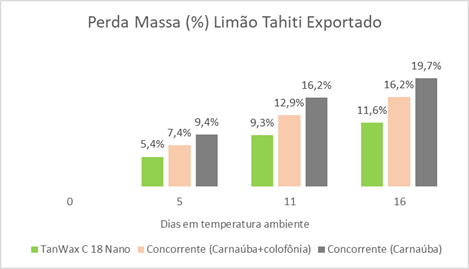

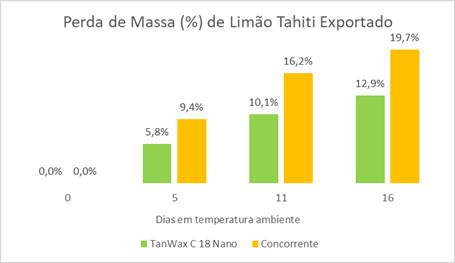

the graphs below, the results in Tahiti lemon exported and evaluated in Europe show that TanWax C 18 Nano, presents consistent results in the reduction of mass loss. This product has the potential to serve European markets that seek a more natural appearance, with less shine and high quality.

Brazil is the third largest fruit producer in the world, but it is not yet a major exporter. There is a need to improve our processes, the quality of our fruits or our services, not only for exports. The Brazilian consumer is more demanding and that traditionally exporting countries are very attentive to consumer movements.

Thus, we only have one way to protect our market and at the same time export more, which is to invest in quality and innovation, understanding the trends and needs of consumers, offering them excellent quality fruits. Our potential as a country is incredible.