2020/2021 Brazilian grain harvest is estimated in 260.80 million tons (CONAB, 2021), being the most prominent country in the world, and is considered the greatest grower of soybean. The country’s edaphoclimatic conditions are favorable for production, on the other hand, when weather conditions during pre-harvest and harvest are taken under consideration, there are challenging situations regarding grain conservation and quality.

Prof. Solenir Ruffato, at UFMT, Sinop

AgriBrasilis interviewed Prof. Solenir Ruffato, from Federal University of Mato Grosso (UFMT), city of Sinop. Ruffato holds a post-doctor degree in post-harvest from the Federal University of Viçosa (UFV), and researches the quality of grains and perishables; harvest and post-harvest loss assessments; and studies storage alternatives.

In the first part of the interview, Ruffato discussed about the importance of grain storage, how much is lost in post-harvest in Brazil, and compares to other countries’ losses.

Importance of grain storage

Grains are food, therefore it is important its conservation, also it is essential to have products in stock to meet the demand for food, since each grain has its harvest once a year, requiring distribution off-season.

Grain storage allows the farmer or storekeeper to obtain better opportunities and profitability, because they can market their product in the most opportune moment.

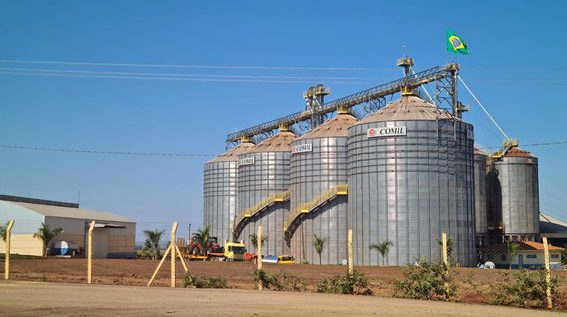

In addition, when farmers have their own storage facilities, there are several advantages, such as, no interference from third parties in the management of the harvest, possibility to store special grains to high demanding markets (leave commodities market); reduce losses, keep quality and higher profits.

The main principle of storage is: dry grain, clean grain, fresh grain. Only meeting these requirements, it will be possible to maintain its quality, avoiding losses.

How much grain is lost in the post-harvest in Brazil

Quantifying post-harvest loss is not a simple task, because many factors interact with each other or exert influence in isolation, and there are specificities of each growing region, as well as type of grain.

Regions that present adverse climate conditions during pre-harvest and harvest are in disadvantage, as the grain will become susceptible to crushing, or breakage, due to high or low humidity, disruption of the integument due to successive drying and rehydration processes still in the field, infestation by pests and microorganisms and damages, such as fermentation, mold and others. Grains that are compromised in harvest will deteriorate faster and will contaminate a larger volume around it.

Information related to post-harvest losses in the country show divergent numbers, ranging from 5 to 10%, sometimes below or above these values, with many contradictions.

In a research carried out by Péra and Caixeta Filho, it was quantified the loss of soybean and corn by post-harvest operation in 2015. From total losses, the highest percentage was observed in storage activities (67.2%), which considered all storing activities in the farm or collecting unit, and for this last it was considered transport from the field. It was followed by road transport (13.3%), port terminal (9%), rail transport (8.8%) and waterway transport (1.7%). They also verified an average total loss of soybean and corn at 1.3% of production, however, this loss was quite variable between states and crops, ranging from 0.22 to 1.67%.

How Brazilian grain losses compare to the world

Data quoted by specialists shows that post-harvest losses in developed countries, especially non-perishable food, such as grains, are below 3%.

Transport logistics is the starting point, so if we take the USA as an example, roads transport, is less than 20% of the production, while in Brazil it is more than 65%.

It is often to have railroads near to the farm, in addition to being cultural that each farmer has his own storage facility.

Taking Canada and the USA as an example, the percentage of storage facilities the farms are over 65 and 80% respectively. In Argentina, it is over 40%, of which many are silos bag, because they, understanding the difficulties and the cost of storage facilities, adapted the technology of hermetic storage in silos bag to their conditions. In Brazil, the amount of storage facilities near to the farm is no more than 16%.

Next week we will publish the second part of the interview about post-harvest losses, in which Professor Solenir Ruffato unveils the reasons for post-harvest losses, what could be done to diminish it and what would be the costs, and finally how much progress the sector made in the reduction of losses and what it could reach.

References:

– Companhia Nacional de Abastecimento. Acompanhamento da safra brasileira de grãos – v.8, n.10 (2021), Brasília: CONAB, 2021 Brasília. Disponível em: <http://www.conab.gov.br> Acesso: julho de 2021.

– PÉRA, T. G. Modelagem das perdas na agrologística de grãos no Brasil: uma aplicação de programação matemática. Dissertação (Mestrado em Engenharia de Produção). Escola Politécnica da Universidade de São Paulo, 2017. 180p.